There are numerous reasons why, we here at Fluidyne, take the extra step to process our stainless steel piping, equipment and supports through the process of Passivation.

Here are a few of the benefits/reasons:

1. Enhanced Corrosion Resistance:

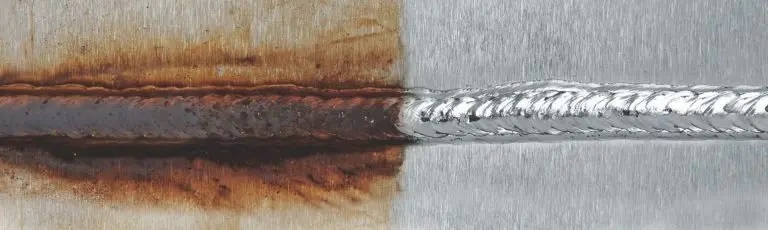

- Contaminant Removal: During manufacturing, stainless steel can pick up contaminants like free iron, which can lead to localized corrosion. The passivation process involves cleaning the surface and the welds with acid solutions that removes these contaminants and restores the damaged oxide layer to prevent corrosion in stainless steel.

- Oxide Layer Formation: Passivation promotes the formation of a chromium-rich oxide layer on the stainless steel surface and welds. This layer acts as a protective barrier, preventing further oxidation and corrosion. This is particularly important in environments where the metal is exposed to moisture, salt, chemicals, or other corrosive elements.

2. Improved Durability and Longevity:

- Prevention of Rust: By removing iron particles and other contaminants that cause rust, passivation ensures that the stainless steel remains rust-free for a longer period. Rust can weaken the metal structure, leading to premature failure.

- Long-Term Protection: The protective oxide layer formed during passivation is stable and self-healing, meaning it can reform if damaged, providing ongoing protection against corrosion. This extends the functional life of stainless steel components, reducing the frequency and cost of replacements and repairs.

3. Bonus: Aesthetic and Cleanliness Benefits:

- Enhanced Appearance: In addition to the benefits listed above, passivated stainless steel has a cleaner, more uniform appearance, making it less likely to harbor contaminants and bacteria.

Overall, passivation significantly improves the performance, longevity, and appearance of stainless steel, making it a vital process in municipal, industrial and commercial applications.

NOT PASSIVATED WELD PASSIVATED WELD